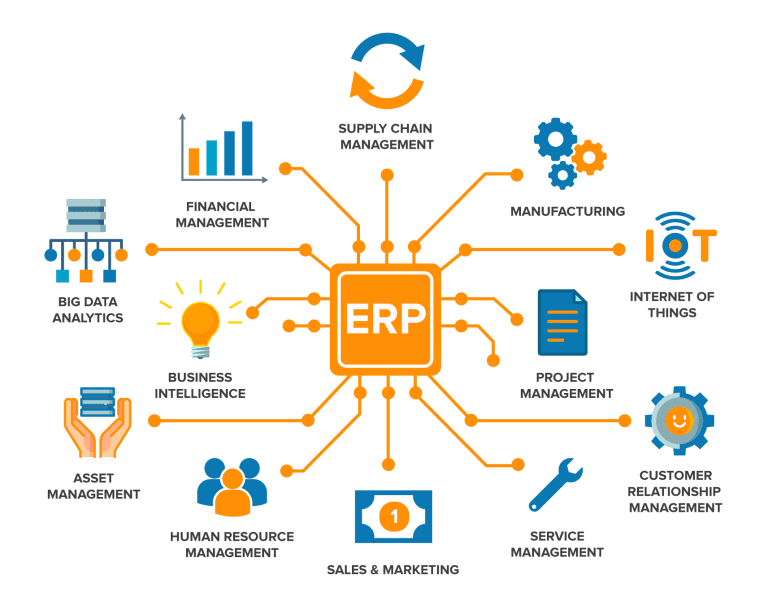

Our company has established an ideal ERP supply chain management system, which accurately matches dozens of inquires with excess inventories of our customers. We aim to help customers maintain balanced and available inventories while reducingoperating costs. We will continuously track discontinued and difficult to procure components. As a result, we minimize any shortages our customers may have to face.

Our components come from original equipment manufacturers (OEMs), original equipment manufacturers (OEMs), and authorized independent distributors worldwide, which ensures product quality.

By leveraging our vetted network of professional electronics suppliers, we can streamline the supply chain process. This enables us to offer consumers high-quality products at competitive prices.

Our inspection team possesses years of experience in PCBA inspection. Professionally trained, they can quickly identify and resolve problems, ensuring optimal quality and performance for every circuit board.

· Automated Optical Inspection (AOI): Utilizing automated optical inspection equipment to inspect surface mount devices (SMD) components, automatically identifying defects such as poor soldering, missing components, and misalignment.

· X-Ray Inspection: Performing X-ray inspection on double-sided, fine-pitch, high-density PCBs. Particularly suitable for examining the internal structure of solder joints, such as BGA and CSP packages, effectively uncovering hidden soldering issues.

· Functional Testing: Performing electrical functional testing according to customer requirements to ensure all circuit board functions correctly. We can provide customized testing solutions tailored to different design requirements.

· Flying Probe Testing: Performing flying probe testing on prototype and low-volume production circuit boards to quickly identify electrical faults or connectivity problems. Suitable for small-batch or non-standard PCBs.

· ICT (In-Circuit Testing): This involves testing the circuitry by directly contacting the pins on the circuit board to verify the correctness of the circuit connections and whether the electrical parameters meet design specifications.